Main Features

Limit switches feedback are a bit different from the HALL-SENSOR or the Magnetic sensor.Limit switches feedback not meant for an electric linear actuator with position feedback, instead, they determine the start and stop points of the linear actuator.

To put it simply, limit switches are installed at both endpoints of the actuator’s stroke and as soon as the actuator rod comes in contact with them, they break off the circuit. This is a necessary measure as the motor does not know when to stop, and if not turned off at endpoints, it can destroy the actuator, itself, or even cause damage to users. The feedback control, in this case, is slightly limited as it is only responsible for collecting position feedback at extreme positions.

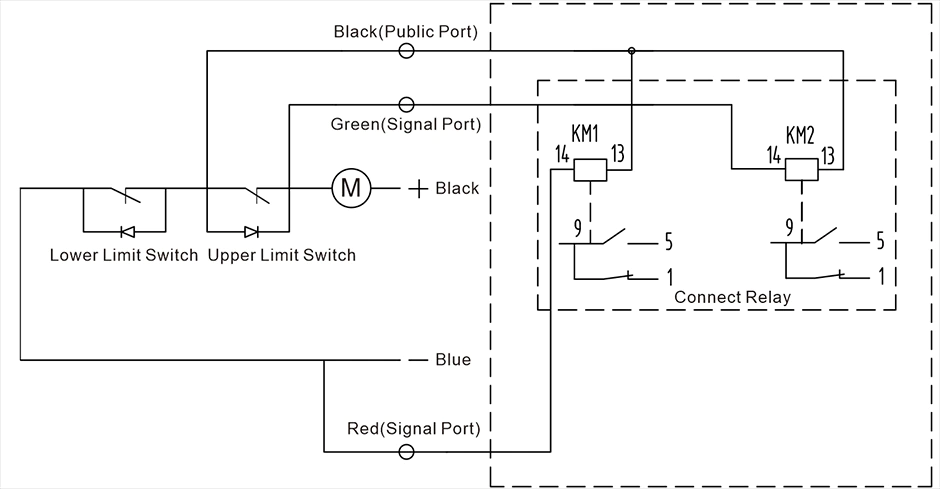

It is suggested to install relays to realize the feedback of the in-place signals at the two highest and lowest positions

How Does Limit Switch Feedback Work in Actuators

Some users’ application needs the limit switch feedback signals to control their system. Instead of using the mechanical trigger to shut off the motor, the application prefers to have an analog signal as part of an integrated control system. Currently, Progressive Automations offer two different configurations when it comes to limit switch feedback.

Option 1:

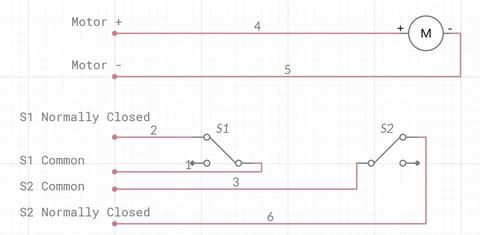

The ‘Common’ for both signals are separated. The extended limit switch and the retracted limit switch will provide an individual signal of normally open and closed to the users. The control system then can take that signal to monitor the positions and drive the motor to stop at the fully extended and retracted position.

Option 2:(Normaly we will add this type if you check with Limit-Switches-Feedback )

It is suggested to install relays to realize the feedback of the in-place signals at the two highest and lowest positions

Very similar to option 1, except now the extended and retracted mechanical limit switch share a common signal. This will still provide the same open and closed state, but with one less wire involved.

Both configurations can provide the signal needed to turn on or off the indicator light and notify the user that the unit has reached its final position. This is a common application for assembly line machinery, where the operator is usually away from the actuator, and they rely on the control panel indicators to alert them on the state of the operation. This can also be used as redundancy in a control loop to provide extra safety assurance to the user.